What is Lanoguard

What is Lanoguard?

Lanoguard is a versatile corrosion/rust prevention and waterproofing spray and grease product with a range of features making it perfectly suited to protecting vehicles, boats and machinery easily and with very limited prep, minimal time and minimal mess when compared to conventional underseals.

Tried and tested in marine and industrial settings, our products are simple to use yet very effective at their job. They can also be used anywhere a regular grease or spray lubricant would be used to waterproof, protect from corrosion and provide anti-seize.

The nature of our products means that, on a cleaned surface, the products simply need to be sprayed on – that’s it. Lanoguard can be applied over stable surface rust, rubber, plastic and metals alike. This gives the product a very quick application time, with little-to-no training required. They’re also silicone-free products and so are body shop friendly too.

UK Customer Support

We have UK based customer support who are just a phone call away. We offer application support for our customers.

How Does Lanoguard Work?

Lanoguard has been formulated from a lanolin base – which gives it three key properties:

- It hermetically seals to the surface it sits on (provides a barrier between the surface and the environment which displaces all oxygen and moisture, making rust chemically impossible).

- It has a natural attraction to metals (it can be sprayed onto existing rust, as it will attract to the metal underneath and slowly push off the oxidation over time.

- It doesn’t require a keyed surface (most conventional products require a ‘keyed’ heavily prepped and de-rusted surface. Lanoguard requires minimal prep because lanolin will happily sit on top of existing rust).

See an article we wrote comparing our lanolin base to conventional rust proof bases here.

These properties work together to bring the benefits of Lanoguard. Our products are:

- Jet wash resistant (up to 3000psi)

- Heat resistant up to 450°C (use on exhaust, engine etc.)

- Non-evaporating

- Non-conductive to 70,000 volts

- Non-flammable

- Non-perishing (they can be used on rubbers and plastics, meaning no masking up is required)

- Petrol and diesel resistant

- Natural (non-harmful to the applicator with minimal PPE needed)

- Non-petroleum based with no overspray (low mess, low clean-up, clean workshop!)

Our products can be used anywhere a regular grease or spray lubricant would be used to waterproof, protect from corrosion and provide anti-seize with a formula that will stay in place doing its job far longer because it doesn’t evaporate like conventional petroleum lubricants. They products are also silicone-free and so are body shop friendly too.

✅ Why Leading Fleet Managers Choose Lanoguard

Expensive structural and chassis repairs

Failed MOTs and vehicle downtime

Decreased resale value

Premature replacement of vehicles

Lanoguard prevents all of that — simply, safely, and affordably.

🔧 Tough on Rust, Easy on Your Operations

No Rust Removal Needed: Can be applied over existing rust

Safe for Electrics, Rubbers & Plastics: Total underbody protection

DIY or In-House Teams: No need for outsourced labour

Our Partners

Book a Free Fleet Discussion

View Our Trade Shop

View all

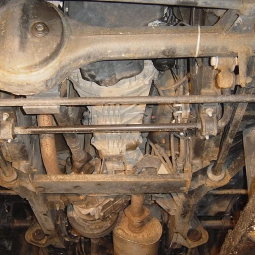

Before

After

Before

After

Before

After

Frequently Asked Questions

Moto Range is designed for all vehicles, bikes, trailers and machinery to name a few. It protects the whole vehicle underbody and chassis from rust, corrosion and electrolysis with a strong barrier coat. Find out more and see our Moto Range.

Marine Range is designed for boats and any machinery submerged in sea water. It protects from rust, corrosion and electrolysis the same as our Moto Range, but also contains marine growth inhibitors to stop barnacle build up on any equipment submerged in seawater. It is safe, non-toxic and marine ecology friendly. Some of its uses include on outboard and inboard motors including electrics, propellers and prop shafts and boat trailers. Find out more.

Outdoor Range is a thinner formula, designed for metal, rubber, vinyl, wood, and almost all materials. It can be used on BBQs, sheds, fences and decking to name a few. It provides protection from corrosion, rust and waterproofs as wells preventing mould build-up in woods and vinyls due to it containing anti-fungal. Find out more.

Lanoguard has been designed for yearly/seasonal applications. It should be topped up at least once a year to ensure continuous protection. Although due to the simple application process there’s no harm in doing an Autumn & Spring application! The product is broken down by UV, so the more it is exposed to sunlight the shorter its life span. Inside box sections or inner chassis for example, it will last longer.

The general rule of thumb is that a little Lanoguard goes a long way, 1.8L of moto spray per application. – is ample coverage for vehicles such as Land Rovers and Pick Up trucks any vehicles over this size we would recommend more than 2L.Click hereto look at our range.

Preparation is very minimal - all you need to do is jet wash your vehicle removing any dirt and grime. Make sure you remove any flaking or loose bits of rust, paint or underseal. Sometimes a wire brush can be used if needed to remove flaking bits. Ensure the vehicle is dry before you apply Lanoguard – it doesn’t have to be bone dry, as Lanoguard will displace moisture to an extent, but ensure you do not apply to a dripping wet surface. See ourhow to apply page here.

Lanoguard is great for chassis with surface rust. It has a natural affinity to ferrous metals and will bond to the metal underneath any surface rust, it acts as a barrier by hermetically sealing to the surface keeping oxygen and water out - stopping any rust from developing further.

Lanoguard reaches its final state around 7 to 10 days after application. Day 0 it is “oily” day 3 “soft” and final state is dry to the touch, but you know something is there. Like a candle to feel. Maybe a little softer. It dries to a clear / transparent semi satin wet look and stays that way for some months eventually dulling a little. But always stays clear; and of course, you can jet wash it to clean it back to how it was when you put it on. It is best to not drive the vehicle for 24hours to let it get through the first part of the curing process.

Lanoguard is eco-friendly and has green non-hazardous certifications. It does not require special handling, protective clothing or disposable gloves, which all add to the carbon footprint of utilising a product that is hazardous. The primary ingredient of Lanoguard is Lanolin which is a very ecologically safe and sound base. In fact, an entire dam in New Zealand was moved down river on a base of Lanoguard marine grease which shows you how the river authority was not concerned about any toxins that would be left as a result.